Europe - 94% of all used tyres collected and treated in 2016

Date

Sections

Brussels, 2 May 2018 – ETRMA, the European Tyre and Rubber Manufacturers’ Association, has consolidated Used Tyre (UTs) management data for 2016 covering 32 countries (EU28, Norway, Serbia, Switzerland and Turkey).

The detailed analysis of the data (see Table in Annex) shows that, compared to the previous year, the 2016 Used Tyres arisings in Europe (3.9Mt) increased by about 66.000 tonnes (+2%) whilst the reuse of part-worn tyres (comprising casings used for retreading on the domestic market, export & domestic second hand markets) dropped by 5%. This means that, after sorting, an ELT arising of about 3.29 Mt remained for further treatment, i.e. an additional 100.000t of ELTs compared to 2015.

The main learnings from 2016 ELT Management practices can be summarised as follows:

- ELT granulation continued being strong (+9.3% vs. 2015)

- ELTs sent to energy recovery slightly increased (+2%)

- Civil engineering uses of whole or shredded ELTs shrunk by 3% as did the reuse of tyres as blasting mats and dock fenders (-15% vs. 2015).

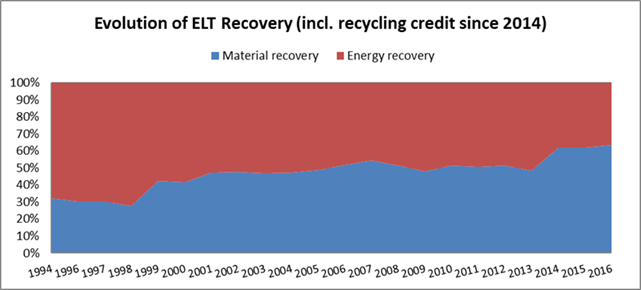

- The inorganic content of ELTs1 processed in cement kilns is physically incorporated in the clinker, hence effectively recycled. This reality is reflected in the data reported since 2014 (see below charts).

Breakdown by application

Expansion of EPR model

As observed for other waste streams, the EPR model for tyres further expanded in Europe with 3 new countries (Czech Republic & Slovakia in 2016 & Ireland in 2017), leading to the creation of ELTma CZ, ELTma SK and Repak ELT as collective schemes approved by national authorities. In 2018, 23 countries operate under an EPR regime for tyres representing about 65% of EU arisings. Some discussions seem to have recently kicked-off in the UK to study the feasibility of introducing an EPR regime for tyres.

“The tyre industry clearly supports the EPR model”, said Mrs. Cinaralp, ETRMA Secretary General, “when it is backed by clear statutory requirements and provides a separate line on the invoice, showing the environmental contribution for ELT management, ensuring full transparency for both national authorities and to the end consumer”.

She nevertheless added that “the latest market trends seem to indicate a saturation of the ELT granulation market in Europe”. It is of paramount importance that new market outlets are developed for ELT granulates. National Circular Economy Plans and Waste Framework Programmes should incentivise this, as exemplified by the Spanish PEMAR 2016-2022 (State Framework Waste Management Plan), promoting the use of ELTs in asphalt rubber, a very promising market, which is yet underexploited. “EU harmonised end-of-waste criteria for ELT granulates & powder are also needed to ensure a level playing field between virgin and secondary raw materials” concluded Mrs Cinaralp.

1 On average, 25% by weight of the ELT flows sent to cement kilns is composed of steel, silica and other inorganic fraction, which is integrated in the clinker.

***ends***

For further information:

Mr. Jean-Pierre Taverne, EU Coordinator End-of-Life Tyres & Circular Economy

Tel: +32 2 218 49 40 or jp.taverne@etrma.org